- Monday - Saturday 8 am to 5 pm

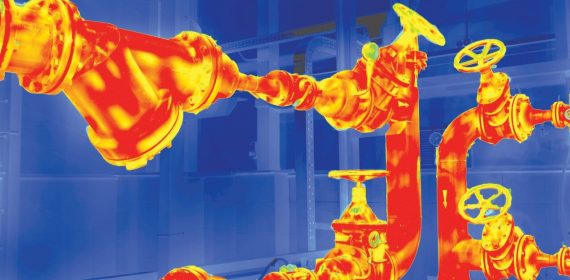

Infrared Thermography

- Home

- Infrared Thermography

What is Infrared thermography?

Infrared thermography testing dubai is an advanced technology that uses specialized equipment which detects infrared energy emitted from objects converts it to temperature and displays image of temperature distribution.

All objects emit thermal energy (heat) in the form of electro magnetic radiation in the IR spectrum. The hotter the object is, the more intense the infrared radiation is emitted.

This radiation is, however, outside of the human eye range. IR thermography is used to detect image, and measure this radiation. By detecting areas of abnormal temperature, IR thermography can diagnose problem areas and their severity. Malco is one the best Infrared Thermography service provider.

What is the importance of Infrared thermography – its role in maintenance and loss prevention?

Infrared (IR) thermography is a non-destructive inspection technique that can pinpoint concerns in industrial electrical and identify impending failures in electrical equipment, production machinery, fired equipment, such as boilers and furnaces, utility supplies and prevent business interruptions.

Why IR surveys Are Important?

IR surveys are an investment in the safety, productivity, and profitability of facility. Insurance industry loss statistics indicate that more than 30 percent of all fire losses are electrical in origin, resulting in electrical failures being the single most likely cause for industrial insurance claims and more important to the small-business owner, even if an electrical failure doesn’t cause a fire, it can result in equipment breakdown and productivity loss.

In today’s increasingly competitive world, even a short-term production loss could result in long-term client loss or business interruptions.

- Infrared Application – Electrical/Mechanical.

- Monitoring electrical systems (Finding hotspots).

- Preventing arc discharge and insulation damage.

- Pinpointing electric motors.

- Checking transformers.

- Locating grounds in circuits.

- Spotting energy loss sources.

- Insulation (wet, damaged, coverage).

- Valves (leakage, blockage).